-40%

TRANSPARENT COLOR TINT KIT RED YELLOW BLUE 4 EPOXY RESIN 1.OZ EZ DISPENSE TUBES*

$ 14.63

- Description

- Size Guide

Description

MAX COLOR TINT KITRED-YELLOW-BLUE

1 Ounce Of Each Color In Easy Dispense Squeeze Tubes

MAX COLOR TINTS are specially formulated transparent color tints for epoxy resin systems. These tints are dispersed in an epoxy functional base resin that takes part in the chemical crosslinking reaction that will not affect the cured mechanical performance of the base epoxy resin used. Other color tints are typically dispersed in a non-reactive binder, which affects the cured performance of the resin system.

MAX COLOR TINTS can be blended with each color to create an infinite number of color shades, and saturation.

Use the MAX COLOR TINT to create transparent colored resin system suitable for formulating tinted coatings or castings.

USE THIS CLEAR RESIN SYSTEM SUITABLE FOR CASTING AND COATING APPLICATIONS

MAX CLR A/B

LOW VISCOSITY VERSION EXTENDED POT LIFE AND IMPROVED FLEXIBILITY

FDA COMPLIANT COATING FOR DIRECT AND INDIRECT FOOD CONTACT

AVAILABLE KIT SIZES

MAX CLR A/B 24 Ounce Kit:

https://www.ebay.com/itm/222623963194

MAX CLR A/B 48 Ounce Kit:

https://www.ebay.com/

i

tm/311947320101

MAX CLR A/B 96 Ounce Kit:

https://www.ebay.com/itm/222625338230

MAX CLR A/B 1.5 Gallon kit:

https://www.ebay.com/itm/222626972426

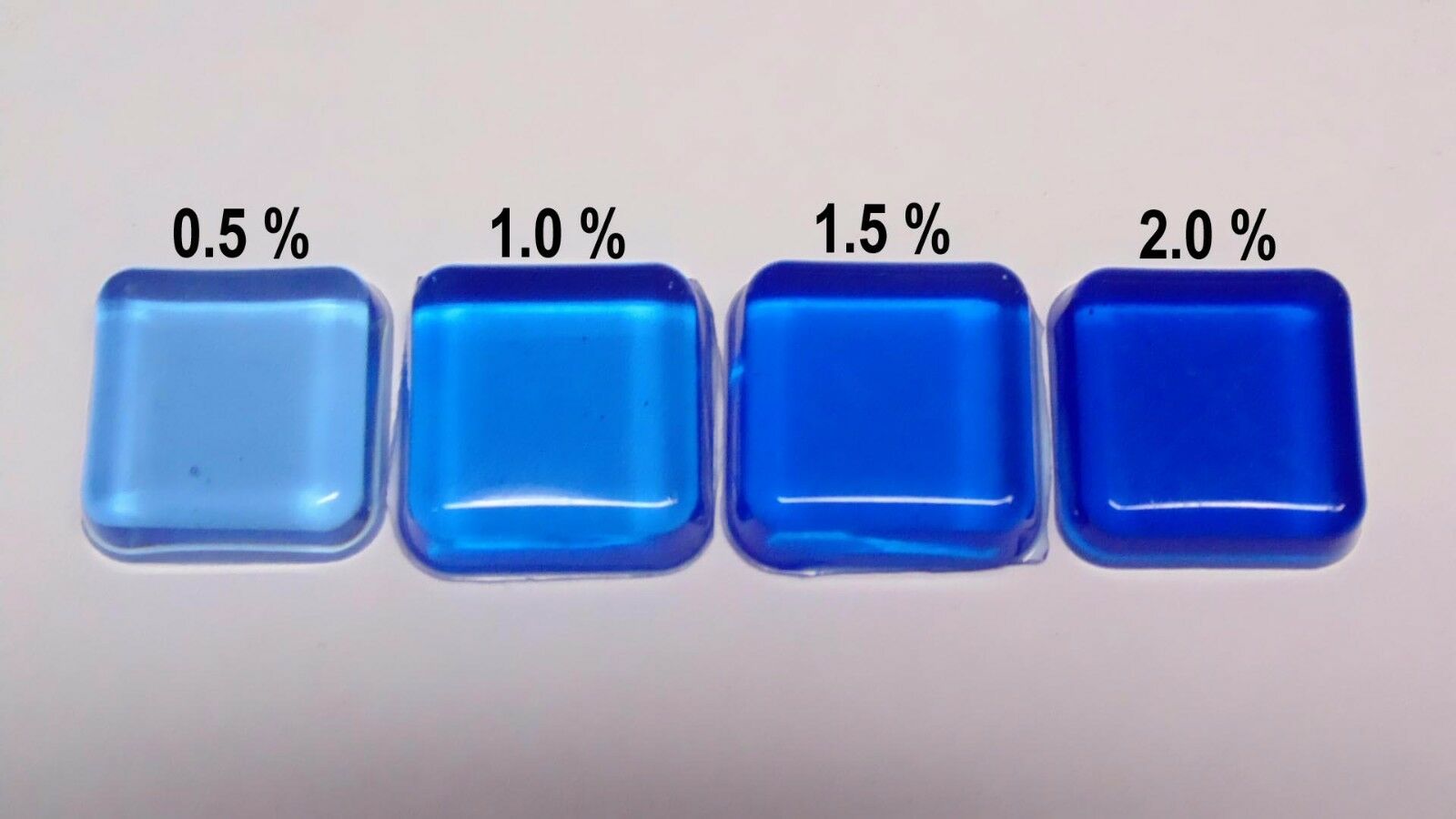

The degree of color saturation can be varied by the amount of the MAX COLOR TINT added to the base resin system.

USAGE

The kit comes with the three primary colors which can be blended in varying ratios to achieve other colors and hues and still maintain transparency. These are very powerful tinting colorants; make sure to meter the level of addition slowly and carefully. To ensure color saturation repeatability, use a digital scale to measure the amount of addition to the resin.

Start by adding the tinting colorants to the PART A or resin component until the proper level of color saturation is achieved. Allow the tinted PART A to sit for 3 to 4 hours to allow any mixed air bubbles to outgas from the mixture.

Once the mixed bubbles have outgassed from the colored PART A add the proper amount of curing agent, mix well and pour into your casting mold. Allow the cast to cure for 24 to 36 hours at 75 degrees Fahrenheit and demold.

Please review the posted usage information on the item page for the proper usage and other pertinent information.

MAX COLOR TINT-BLUE mixed with MAX CLR A/B base resin at varying amounts

The use of a weighing scale is highly recommended for proportioning any chemical reactants. Using volumetric measuring is fine, however, weighing each component accurately will yield better cured mechanical properties, batch repeatability, and less waste from mixing over-sized batch. Use this digital scale to measure and proportion up to a 10th of a gram accuracy.

Purchase this scale with any of product offering and the shipping cost of the scale is free.

Please request a total before paying for combined shipping savings.

https://www.ebay.com/itm/222630300203

Scale Usage Demonstration

Click on the image to play video.

Three Primary Colors

Three Secondary Colors

Six Tertiary Colors

They form the full spectrum of colors which progress around the Primary Color Wheel in gradual increments.

With just these twelve colors, you can literally mix an infinite number of color schemes. Most of the time you will modify these twelve basic hues by mixing in other colors.

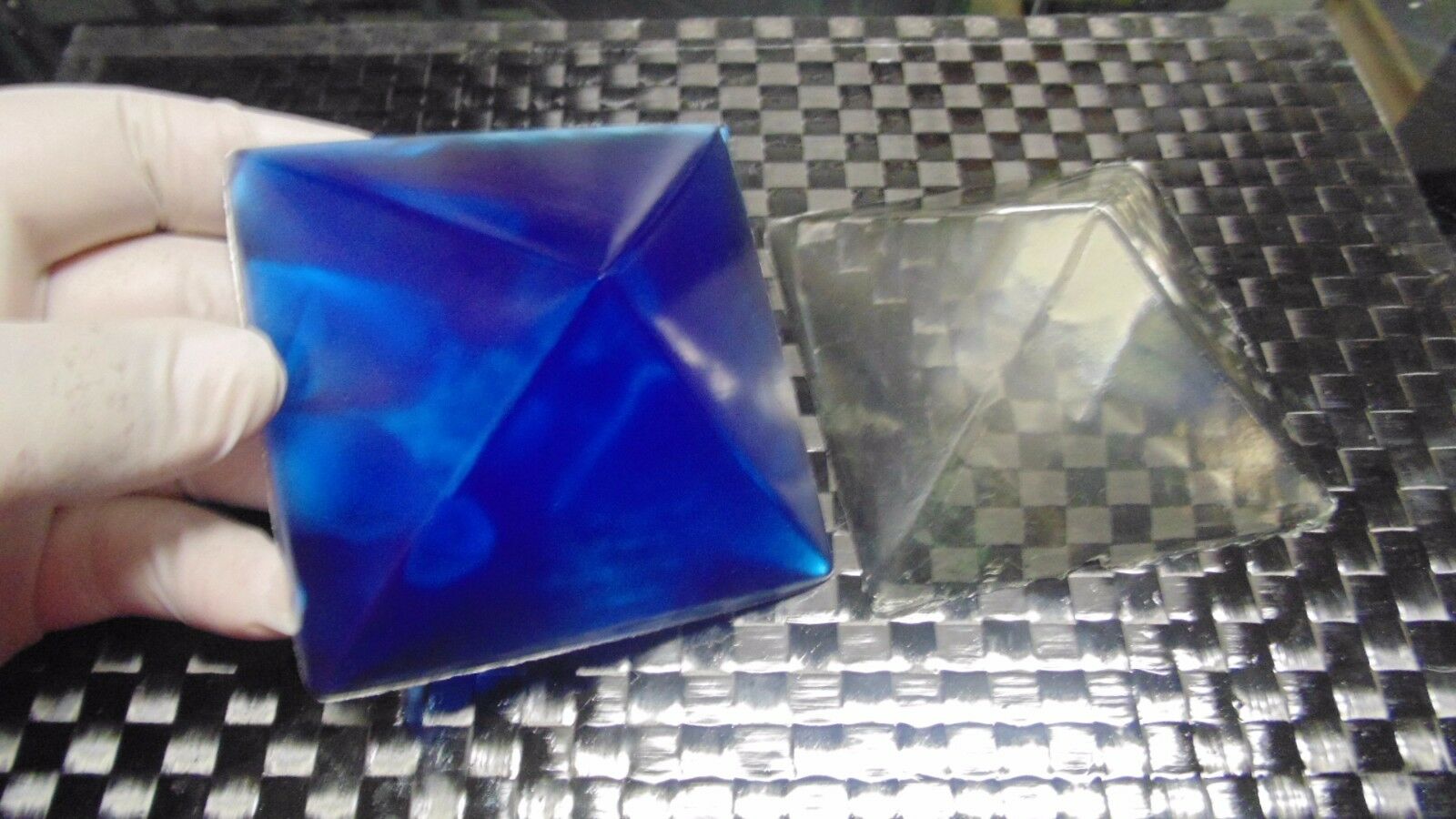

MAX CLR A/B Clear Cast

MAX CLR A/B with 1.5% MAX COLOR TINT-BLUE

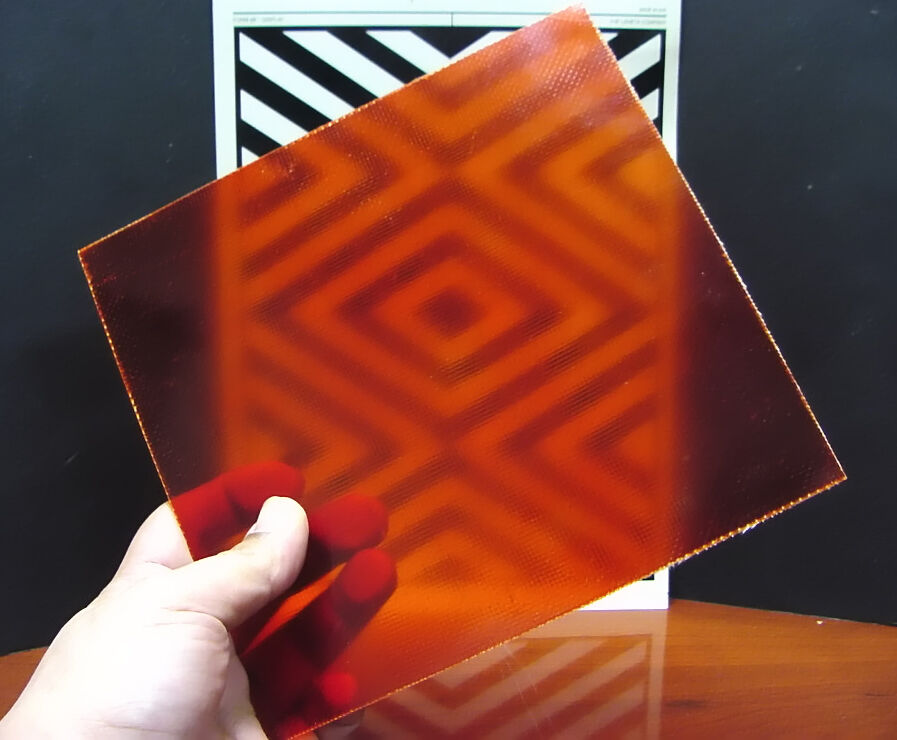

MAX COLOR TINT -YELLOW with MAX CLR A/B

MAX COLOR TINT -RED with

MAX CLR A/B Silicone Cast Tail Light

IMPORTANT NOTICE

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product.

The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application.Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval.The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts and Polymer Composites Inc. laboratories using materials under controlled conditions. Data of this type should not be used for specification fabrication and design. It is the user's responsibility to determine this product's fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to the refund of the purchase price or replacement of the product within the agreed warranty period. PolymerProducts and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.